Fume Extraction

We offer a wide range of innovative welding fume extraction systems. Discover our tailor-made extraction solutions for industry and skilled trades.

Teka Fume Extraction - Sole Agents In Ireland

Welders face a series of risks from dangerous substances that could mean they face time off work for illness or even early retirement. Different welding methods give rise to different amounts of fumes containing various concentrations of hazardous substances. The smaller the particles, the more dangerous they become because they are easier to breathe in deeply in the lungs. The amount of welding fumes that are formed depend upon the type of welding and materials used.

What are welding/cutting smoke/fumes?

Welding smoke and fume are toxic metal smoke/fumes produced during welding operations. They usually have different compositions, depending on the metals that are used for welding. Therefore they contain several contaminants. It is important to differentiate between the welding fume and the pulverized coal.

95% of the welding fume addict to the filler material as the conductor or the electrode. Pulverized coal is different to welding fume. Here it is the other way around: 95% of the pulverized coal depends on the material you cut. Attention should be paid to welding fume which is no gas but rather basically particle. This is the genuine risk at a work place.

Some of the most toxic are:

Aluminium, Beryllium, Cadmium oxides, Chromium, Copper, Fluorides, Lead, Manganese, Iron Oxides, Molybdenum, Nickel, Vanadium, Zinc Oxides, Carbon Monoxide, Hydrogen Fluoride, Nitrogen Oxide, Ozone and Hexavalent Chromium! Welding and cutting smokes/fumes pass our lungs and thus the whole body. We inhale them with the air we breathe.

Health effects:

- Irritation of eyes, nose, and chest

- Coughing

- Shortness of breath

- Bronchitis

- Fluid in the lungs

- Inflammation of the lungs (Pneumonitis)

- Loss of appetite

- Cramps

- Nausea / Vomiting

- Chronic lung problems (such as Bronchitis, Pneumonia, Asthma, Emphysema, etc.)

- Lung Cancer

- Cancer of the Larynx

- Cancer of the Urinary Tract

- Parkinson disease

- Skin diseases

- Hearing Loss

- Gastritis, ulcers of the stomach

- Kidney damage

- Infertility

- Heart disease

The most dangerous and frequency of gases is active oxygen

This is most damaging. But it is possible to avert the accumulation. For this purpose it is essential to partition the work place. To eliminate the acquisition of the UV radiation it is important to cover or to put away reflective objects. This is feasible with vertical blinds.

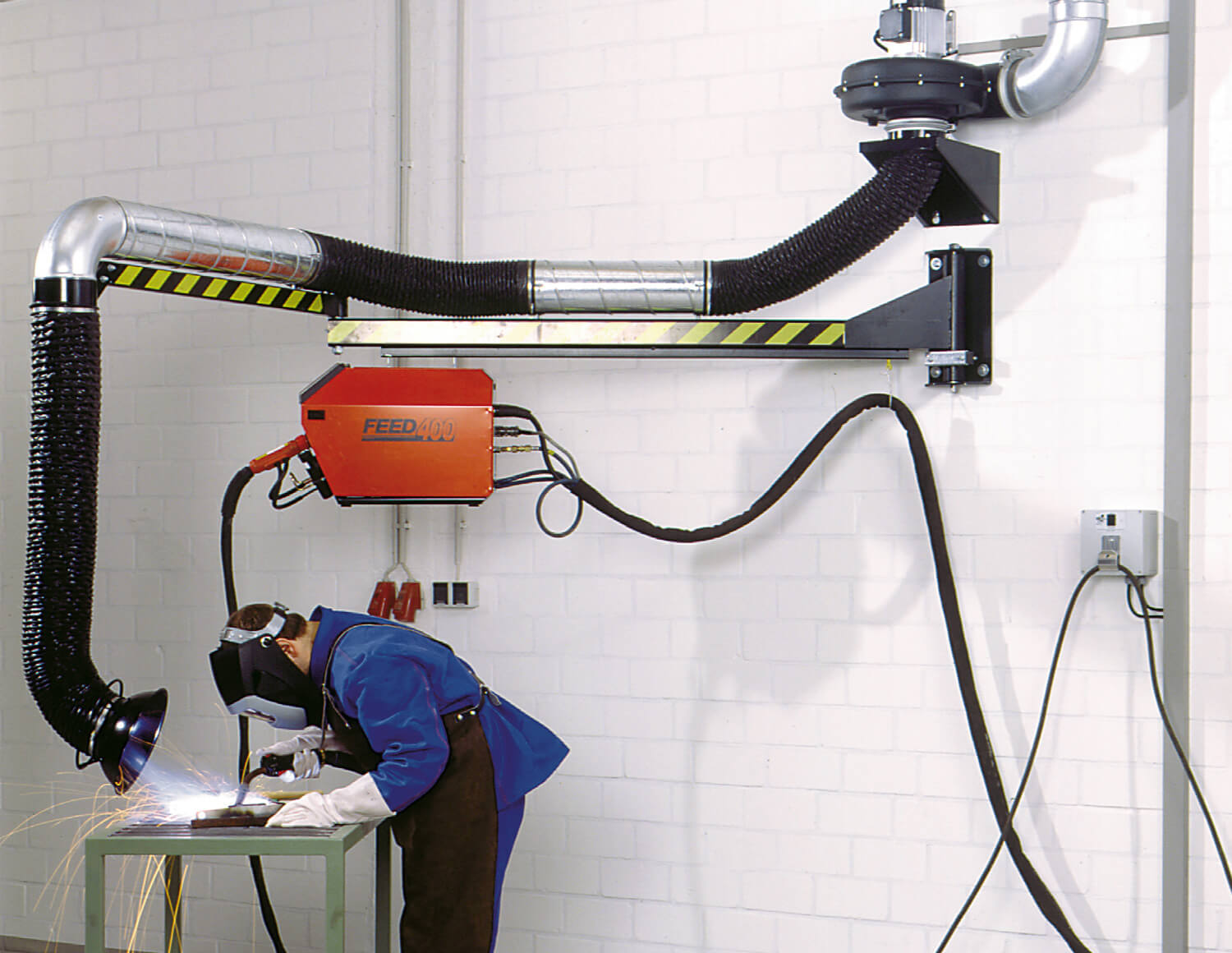

Ventilating a complete workshop does not prevent the welders breathing zone from hazardous substances. Local point extraction is the most effective method.

The hazardous substances are captured right at the source/torch before they reach the welders breathing zone. This is the only guarantee of a sufficient protection to provide clean breathing air for welding and cutting applications. General ventilation like open roofs, open doors and windows or simple roof and floor fans only spread the hazardous materials all around the workplace and working halls.

In co-operation with local German and European Health and Safety Organizations we recommend the following approach to protect workers according the legislation according to DIN and EN- ISO norms/laws. One of the most important tools to handle an adequate extraction solution is the German/ European guideline “Schweissen ohne Rauch” (Welding without smoke) of the German association of machine manufacturer. (VDMA)

This guideline provides some important inputs how to handle a proper filtering and extraction system. The VDMA worked out these inputs together with the European administration for Health and Safety according to the most important laws, standards and norms:

Have a query?

If you have any question about our range of fume extraction units or any products on our website please do not hesitate to call us on: (01) 452 4244

© 2019 Kelly’s Welding & Engineering Supplies Ltd. All Rights Reserved.